3D Laser Printing System Will Make Engine Components For NASA’s Space Launch System

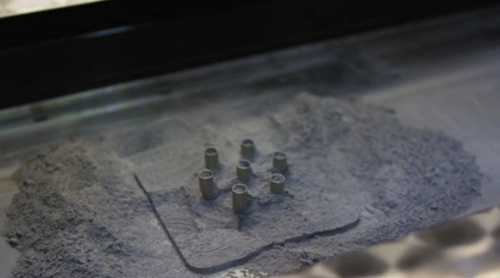

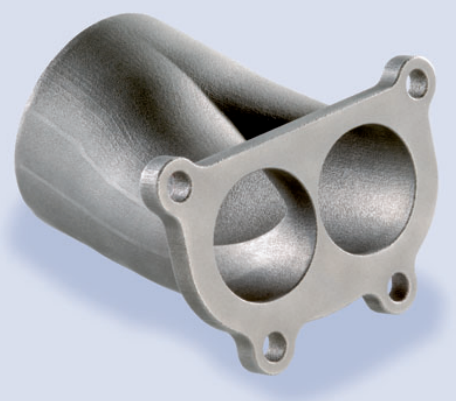

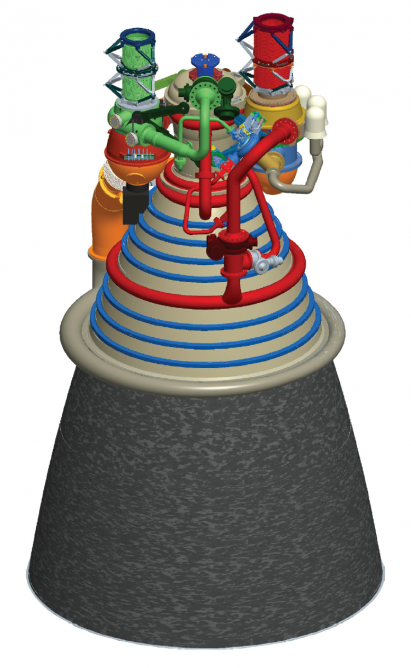

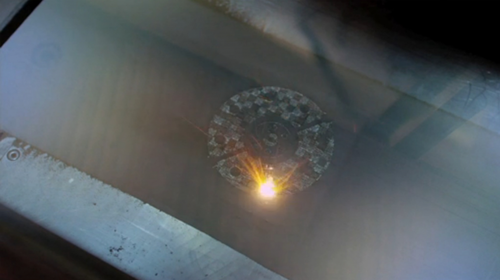

NASA has recently implemented a new method “selective laser melting“ (SLM) of the 3D laser printing system to produce rocket engine components for its next-generation Space Launch System (SLS). Rocket engines deal a lot with highly corrosive or cryogenic liquids, hot gases or destructive stresses and vibration. NASA is currently using an M2 Cusing Machine designed by Concept Laser for the Space Launch System. The machine is similar to other 3D printers, though it doesn’t bring polymers to set, the M2 works in stainless steel, hot-worked steel, aluminum, titanium and nickel alloy by means of a 200 W fiber laser. As a result, the parts with complex geometries and precise mechanical properties are produced from a three-dimensional computer-aided design. Instead of building parts in simple sub-stages and then sticking those together, this process can be now made at one go, thus manufacturing time will be reduced, there will be less production problems, and besides production costs can be reduced up to 50%. Moreover, M2 is designed to produce the parts in a neutral atmosphere without supervision, so it will bring improvement to safety. NASA aims to use the M2 to print engine parts for the J-2X engine, which is meant for the upper stage of the SLS. Structural and hot-fire tests are ahead, and the first SLS unmanned developmental flight is planned for the end of 2017.

Via:gizmag.com

| Tweet |